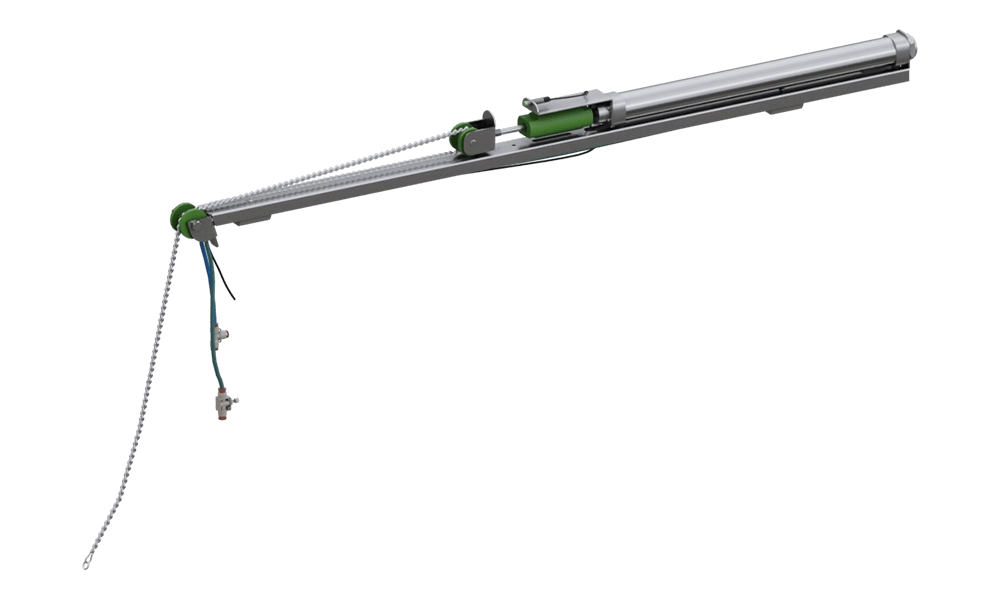

Description

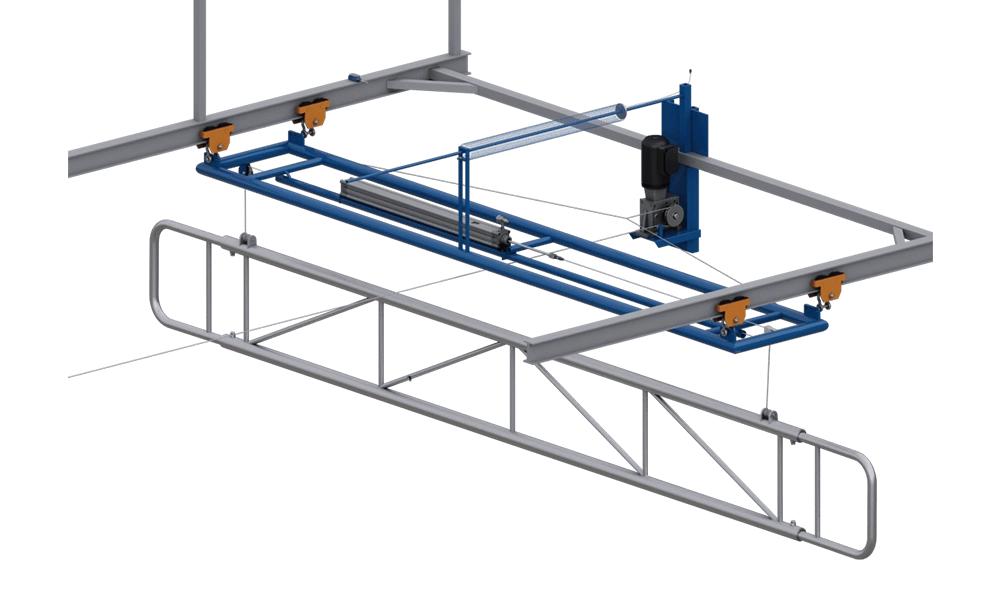

This system automatically lubricates the traction beam of the platform, getting rid of the labor needed for this task.

It also assures the correct and permanent lubrication, extending the life cycle of the driving system components.

The pump is interconnected to the rotation control panel in such way that it only operates when it is rotating. If during a spraying cycle the platform is stopped for any reason, the grease spraying is also suspended, reestablishing itself once the platform starts moving again.

Benefits:

• Allows a more uniform greasing of the rotary beam in time.

• Programmable according to the rotation speed of the platform.

• Saves time and labor by just requiring a periodic visual inspection of the system and of the refilling of the pump when required.

• The pump can be refilled with a pneumatic or lever pump directly attached to a grease bucket.

• It has the function of applying grease out of the programmed schedule.